Your Bill of Rights

04/04/22 08:32

These are ten rights I honor for all my clients. It might seem like overkill but this is how I ensure that the right job gets done for a fair price. It isn’t always the job I thought was needed when I made an estimate. Conditions change. Finances change. Aesthetics change. And, sometimes, people change their mind about some aspect of a project after they see what it will look like. That is pretty normal because most people don’t have a clear idea of fine details about fence and gate projects.

Therefore I must be nimble in my business. It must be easy to change gears and I have to be certain to hear when my client speaks about changes, concerns or problems. I have to be able to hear it and respond with a plan to provide what they prefer. Sometimes it means stopping a project and making an estimate for a different project, but usually that isn’t necessary. What is necessary is to make the right thing for the lowest cost. Nobody cares how economical it was to make the wrong thing. Only making the right thing for a client fulfills my end of the value proposition that ultimately yields payment for my service of making fences.

I’m here to do an excellent job, start to finish. I do all the work myself. I’ve learned from every mistake I’ve ever made and I don’t make those mistakes anymore. I have over 50 years of woodworking experience. I teach woodworking classes at Ace Makerspace in Oakland. I was an expert woodworker before I ever made a fence. Furniture requires an accuracy of 1/64” of an inch. Fences require an accuracy of 1/16”, for example where a lateral 2x4 meets a 4x4. But, I am usually much more accurate than that because I use extraordinary tools, such as my cordless Milwaukee 12” Double-bevel sliding compound miter saw which can cut a miter 60º in one direction and 55º in the other, and can cut a 2x12 at a 45º angle. I run a 100 tooth blade on it for glass smooth cuts. When I make fences on hills I cut boards to an accuracy of about 0.1º. Redwood lasts for many years unless it touches soil. A good job is a joy for a very long time.

There aren’t a lot of people who do this kind of work, but there are plenty of companies that do. The larger the project the more likely a big company will end up costing you less. I can’t be sure but around 200 feet I think a fence company will be a better deal and that will get the work done in about a week. It would take me at least a month to build that much fence and possibly more depending on how hard it is to get the posts ready for a fence. I routinely tell people who want very large fences that I’m not going to be able to compete on price with a big fence company for big fences.

But, big fence companies won’t come out and build just a gate for you. Or repair your fence by replacing a few posts, giving it years more life. A big fence company will not reuse post bases to minimize the carbon footprint of the project without increasing the cost of the project. I will.

A handyman can do all the same kinds of work that I can do; however, it probably won’t be done as well. It takes the right tools and techniques to build a straight and vertical fence. Building a gate that will work for a lifetime is subtle, right down to the angle, position and pre-drilling for all the screws. I use the right kind of wood and the right kind of fasteners and the right kind of concrete when it must be used. The wrong kinds lead to failure later on.

Fence companies and handymen also don’t adhere to my client bill of rights. I do.

Therefore I must be nimble in my business. It must be easy to change gears and I have to be certain to hear when my client speaks about changes, concerns or problems. I have to be able to hear it and respond with a plan to provide what they prefer. Sometimes it means stopping a project and making an estimate for a different project, but usually that isn’t necessary. What is necessary is to make the right thing for the lowest cost. Nobody cares how economical it was to make the wrong thing. Only making the right thing for a client fulfills my end of the value proposition that ultimately yields payment for my service of making fences.

The ability to reliably adapt to a client’s changing needs is essential to success

My Client’s Bill of Rights

- You have a right to a detailed estimate and a list of assumptions underlying that estimate

- You have a right to a detailed invoice that explains how every penny was spent

- You have a right to ask what I’m doing and why at any point in the project. I always have time for your questions except when the concrete is wet.

- You have a right to my best work. If I’m too tired to work hard my day is over.

- You have the right to change your mind. It isn’t always free of cost and adding new work may require a change of schedule, but I will always shift to do what you want if it is work I normally do.

- You have a right to contiguous execution of your project. I won’t leave your project to work on another until yours is done unless it has changed scope significantly.

- You have the right to cancel a project whether it has begun or not; however, if it has begun you are still responsible for payment for materials already purchased and labor already completed.

- You never have to pay money if no useful work was done.

- You have a right to a daily status report that includes details about what was done, how much money was spent, how many hours of labor were spent, and details about any problems, concerns, questions or issues that have come up.

- If we talk and make any changes to the definition of the project I will always write those changes in a status report so they are in writing.

I Love Building

I’m here to do an excellent job, start to finish. I do all the work myself. I’ve learned from every mistake I’ve ever made and I don’t make those mistakes anymore. I have over 50 years of woodworking experience. I teach woodworking classes at Ace Makerspace in Oakland. I was an expert woodworker before I ever made a fence. Furniture requires an accuracy of 1/64” of an inch. Fences require an accuracy of 1/16”, for example where a lateral 2x4 meets a 4x4. But, I am usually much more accurate than that because I use extraordinary tools, such as my cordless Milwaukee 12” Double-bevel sliding compound miter saw which can cut a miter 60º in one direction and 55º in the other, and can cut a 2x12 at a 45º angle. I run a 100 tooth blade on it for glass smooth cuts. When I make fences on hills I cut boards to an accuracy of about 0.1º. Redwood lasts for many years unless it touches soil. A good job is a joy for a very long time.

Fence Services

Fences aren’t that complicated so it is possible to get very good at a small collection of techniques. That is part of why I focus on fences, gates and pergolas, and those made only from construction heart redwood. Others include that fences and gates don’t require permits as long as you stay within city guidelines, and that almost every house has a fence. They only last so long, say 50 years. That means each year 1 out of 50 houses will need fence work.There aren’t a lot of people who do this kind of work, but there are plenty of companies that do. The larger the project the more likely a big company will end up costing you less. I can’t be sure but around 200 feet I think a fence company will be a better deal and that will get the work done in about a week. It would take me at least a month to build that much fence and possibly more depending on how hard it is to get the posts ready for a fence. I routinely tell people who want very large fences that I’m not going to be able to compete on price with a big fence company for big fences.

But, big fence companies won’t come out and build just a gate for you. Or repair your fence by replacing a few posts, giving it years more life. A big fence company will not reuse post bases to minimize the carbon footprint of the project without increasing the cost of the project. I will.

A handyman can do all the same kinds of work that I can do; however, it probably won’t be done as well. It takes the right tools and techniques to build a straight and vertical fence. Building a gate that will work for a lifetime is subtle, right down to the angle, position and pre-drilling for all the screws. I use the right kind of wood and the right kind of fasteners and the right kind of concrete when it must be used. The wrong kinds lead to failure later on.

Fence companies and handymen also don’t adhere to my client bill of rights. I do.

Area of Service

02/04/21 17:31

Area of Service

Summary:

After considering the carbon footprint of my service I realize that my vehicle is probably the most significant portion of it. I can’t provide my service without a van; however, I can minimize how much I use it.So I’m reducing my service area for new projects. Here’s what included:

<< Updated 4/4/22 >>

- Oakland Northwest of Highway 24 and north of I-580

- Emeryville and Berkeley

I will always adjust gates I’ve made for people, regardless of where I have made them. If I made your gate and it needs an adjustment I’ll come out and do that for free, whether it is within my new service area or not. But all new projects will have to be within my new service area.

Why the Reduced Area of Service?

I’m trying to reduce the carbon footprint of my business.

During the pandemic my policy has been to return home at lunchtime. There I can find food, a bathroom, ibuprofen and whatever else I need to recover from the first half of my workday. Finding all I need while out might be possible, but it carries a much higher coronavirus risk.

That means I make two trips to each work site each day. The further away a project is, the more carbon is transferred to the atmosphere because of the fuel used by my van. And, the carbon footprint of catching coronavirus is very bad, assuming I survive.

Work in the Oakland and Berkeley hills is not working very well for me. It is much harder to drive and harder on my van to get to and through the narrow roads. And the work is often on a hill, or the materials need to be transported up or down a hill to the worksite. It’s a job for younger people than me. Or more people. But, a project on a hill can end up meaning I can work an hour less each day, which ends up meaning even more trips to the job site.

Parking can be very difficult on narrow mountain roads. Double parking might not be possible without completely blocking traffic (which I won’t do). If I have to park very far away it adds a significant amount of time and energy to a project further reducing the work I can accomplish in a day, leading to more trips to the work site.

I’m very sorry to have to say “No” to people if this is the only reason. But, I’m overwhelmed with business in all areas; my work queue is long enough that it works out to effectively be “No” anyway for many people whether they are within my service area or not.

What is the Carbon Footprint of my Greenest Fences?

While the wood itself is probably carbon-negative at best and carbon-neutral at worst, the rest of my business has a much worse carbon footprint, and there are some environmental considerations as well.

I use techniques that minimize the carbon footprint of the resulting fence by reusing post bases and often by reusing fence boards.

Reusing materials doesn’t reduce the carbon footprint. It merely doesn’t add to it. It’s a good thing in its own right, to maximize the useful lifetime of everything that gets made; however, it doesn’t move the carbon footprint into or even towards the target of a negative carbon footprint business.

These parts of my business all have a bad to very bad carbon footprint:

- The tools that I use are made from metals and plastic, few if any of which are from recycled sources

- I use concrete when needed

- I use welded wire fencing and T-stakes, few if any of which are from recycled sources

- I use screws and other fasteners in large quantities, few if any of which are from recycled sources

- Most of the waste I handle cannot be recycled and must be landfilled: landfilled wood will eventually turn into methane which is at least 25x as bad as CO2 for the atmosphere

- The the carbon footprint of the fuel and oil I use in my van is by itself the biggest part of the carbon footprint of my business.

These things all have bad to very bad environmental effects:

- I use chemicals known to the state of CA to cause cancer and reproductive harm. For example, wood preservative, which I have to aerosolize to distribute to where it is needed. There is always overspray.

- I handle, cut and install pressure treated wood, producing sawdust and waste wood

- The batteries that drive the tools I buy are an environmental burden to say the least

- The tools I have are not recyclable

- My vehicle whether gas or electric will use up tires and other consumables over time

- An electric vehicle will have a battery system just as bad as my tools, but probably at least 100x as big

- My gas van has two big 12v batteries in it: one for starting the car and one for a 1000 watt inverter (tied into the alternator for charging when the van is running). These big lead-acid batteries are bad for the planet.

As you can see the carbon and environmental effects of building even the greenest fence I can build is still likely to have an overall positive carbon footprint when all aspects of my business are taken into account. That is, it contributes to the planet’s CO2 problem.

This is critical:

The money I earn making fences carries the carbon and environmental footprint of my fence business.

How Can I Reduce the Carbon Footprint of My Business?

Since my gas van is the biggest component of my carbon footprint, would replacing it with an electric van reduce my carbon footprint enough to make building a green fence carbon negative? I don’t think so. It isn’t merely a matter of comparing the carbon footprint of the energy used for each.

I would definitely say this though: there are other big influencers in the footprint of a fence project and the fuel is not the biggest.

If you want your fence’s wood to remain carbon negative it cannot be painted.

It must be composted or bio-charred at the end of its life and not landfilled. If it gets painted it can’t be composted and it eventually is 25x as bad as any gains had from using wood to begin with. If you were to burn the wood instead of landfilling it that would be 25x better than burying the wood where it eventually becomes methane. But, you shouldn’t burn painted wood because that will produce dioxins and other highly toxic chemicals. So, painted wood has to be landfilled. That is a bigger effect than the proportion of my carbon foot print that is due to the fuel my van consumes. It is also out of my control, but not out of my influence.

If I have to earn more money to pay for a new electric vehicle, that money carries the carbon footprint of my business. More money = worse for the planet. I don’t have greener ways to make money. The electric van would not in itself even match the carbon footprint of the rest of my business, but of course it would help. But when you add in the fact that the extra money needed for the electric van would also come with its own carbon footprint it begins to seem that the problem is merely being moved, but with the consequence of more debt and higher prices for my customers.

I would rather run a business with a negative carbon footprint, but failing that I’d like to reduce the carbon footprint of my business in ways that don’t compromise what I make for people, and in ways that don’t prostrate me with debt.

The best approach for now is to reduce the amount I drive, regardless of the kind of vehicle I use, and to counsel people not to paint their fences with chemicals that can’t be composted.

But, people need fences repaired and created. That is what I do. What matters most to me is maximizing the service provided while minimizing the carbon footprint, even if I can’t have a negative footprint as I would like. I can still find ways to reduce it.

Reducing my service area is the one step I can take that has an immediate and positive effect on the carbon footprint of my business. It doesn’t increase debt and it doesn’t compromise the results of what I do in any way.

It’s up to me to make the choices that reduce the carbon footprint of my business and this is the lowest of the fruits than hang. I sometimes bang my head against those things… I’m happiest when there aren’t thorns.

Low Carbon Footprint Fences

14/03/21 09:16

One of the goals of my business is to minimize the carbon footprint of my fence projects.

Full disclosure: I drive a big, gasoline fueled cargo van from 2000 because I regularly haul a couple thousand pounds of materials or debris. This is the smallest vehicle that can serve the purpose to which I put it. A smaller vehicle would need to make more trips to transport the same load I can in one trip.

The rest of this blog post is about the fence project itself. These are my “first principles” of reducing the carbon footprint of fences

It is also usually the case that following these first principles also leads to a lower cost project, which is nice.

I’ve already written why concrete is so bad for the planet here. That’s why I try to minimize its use.

Replacing Fence Posts

I often replace posts by reusing the existing post base - I have a good blog post with pictures about how to do that. But, sometimes the post bases have issues, such as:

In the first case the post base simply cannot be reused. It has to be cracked out, at least partially. If it is cracked I remove the cracked parts and leave behind as much of the original post base as possible, unless it is less than half of a post base. If it is less than half I will usually remove it all.

I use fast-setting concrete. I never use “fence post concrete”. The kind I use is quite adhesive and will stick to the concrete already in the hole. It still needs to be 2” thick or thicker at its thinnest points, which are near the corners of the post. If the original post base isn’t at least 2” thick at the corners of the post it probably won’t survive the process of driving in a new post even if you are able to clear it.

But, in my experience a post base can usually be cleared and reused. I’d say more than 75% of the post bases I deal with are more or less easily reused.

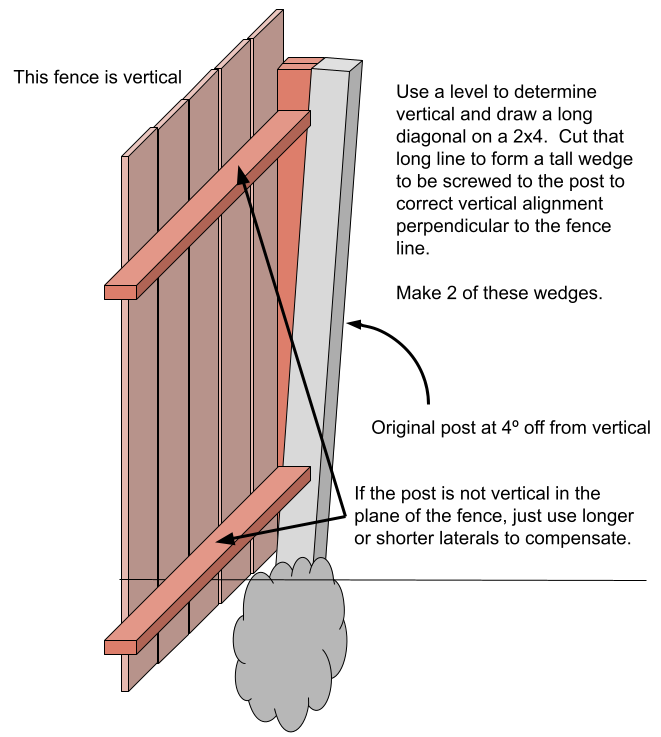

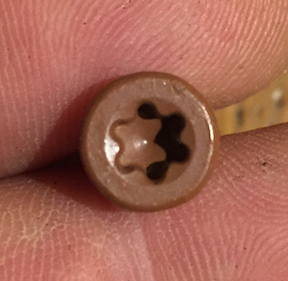

Building a Vertical Fence on Leaning Posts

Recently I repaired and rebuilt two different fences where the post bases had rolled. I replaced the posts but they weren’t in any kind of line and they weren’t vertical. I certainly could have built a fence that wasn’t vertical nor straight but there is a better approach that yields a perfectly vertical fence regardless of the position of the posts. It requires a little more wood and woodworking.

Almost regardless of the fence design, the end result will have to include posts that are in line and vertical. But, only one side of the post needs that. The other sides of the post do not need to be vertical nor in a line.

I add wood to one side of the posts that aren’t plumb and in line. Post bases tend to roll so the angled post would point away from the fence. They can also roll along the fence line, but is much less of a problem because you can just use shorter or longer laterals to compensate for that. The hardest problem is the one that comes up most often: correcting for a post that leans away from the fence.

Typically I add a wedge of wood, but you can also add a wider piece of wood, such as a 2x8. But, redwood 2x8s are expensive and I can cut a 2x4 into two wedges that will work just as well as attaching a more expensive 2x8 to the side.

To check the alignment of the posts I attach a string to both end posts. Typically the posts all lean in the same direction but they might not. I have had fences with snaggletooth posts in all directions that could only be addressed by adding 2x12s to each post. It all starts by finding a straight line that none of the posts cross and building the rest of them out to that line.

To extend a post to the new fence line (defined by the string, which remains during this whole process) I add wedges and shims made from redwood 2x4s. I like using the rough 2x4s instead of the smooth S4S 2x4s because they are slightly thicker and wider.

I add the wedges first and then add shims as needed to reach the fence line.

For the thicker section you can pre-drill a 3/8” hole 1” deep into the wedge and then insert a 3.5” screw into that 1” hole. It grabs the 2x4 at a point 1” below the surface, capturing 2.5” of the 2x4. You’ll need a longer bit to drive the screw at the bottom of the hole. There are longer screws, but they cost more and capturing 2.5” is enough.

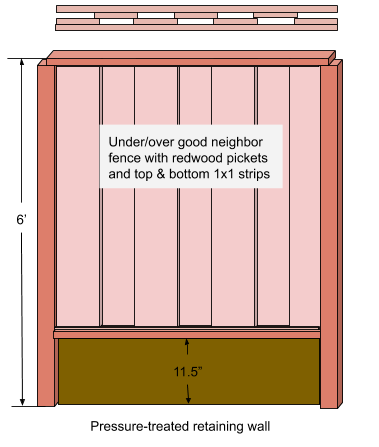

I only ever use T25 star drive screws. I never use Philips head screws or square drive screws; however, I do swear at them and direct my ire toward them when I am forced to remove them.

Once the wedges are on then the rest of the gap from that point to the fence line needs to be occupied by solid wood. I prefer to use the rough 2x4s, but resting across the two wedges. That allows me to add 1.5” at a time. If it is going to need more than one 2x4 I will sometimes add a 4x4 instead. If I do, I drill 3/8” holes 1” deep and insert 3.5” screws in them to secure the 4x4 to each of the wedges behind it.

If I need 3/4” I will use a fence board to fill the gap, but only a really solid red one (construction heart).

If I need other thicknesses I will sometimes rip them from 2x4s on a tablesaw. That makes strips as wide as a 2x4 and the correct thickness for your needs. I attach those last, on top of any other shims and on top of all of the wedges. When you finally attach a fence board there be sure to use longer screws than usual so that the fasteners go through these thinner, custom shims.

It takes about half an hour to add wood to a post to make it have a vertical front. No new post base is needed. A new fence or a rebuilt fence made on the new combination post will be as vertical as the side you prepared with wedges and shims.

Minimizing Waste

There are lots of advantages to minimizing waste. First, there is less to throw away at the dump or in your trash. That is a good thing by itself because it saves you time and probably money if you have a nontrivial amount of waste.

Some waste can’t be avoided, such as rotted or broken wood. But other waste is tied to what you buy and how you use it. I have the luxury of using leftover wood on my next project and that is one way I reduce waste. Another way is in my choice of lengths. If I am building a fence with 6’ sections I buy 2x4x12s. If they are 7’ or 8’ sections I buy 2x4x8s. My goal is less than 10% waste in what I buy. When I do a good job there are only end-cuts left and it doesn’t take long to clean up.

Another aspect to minimizing waste is not assuming the existing fence is all waste. Often the fence boards can be reused with 20+ years of life in them. If you can push a finger into them they are too deteriorated to be used. The laterals may be rotted, but you can put new ones in place and attach all the fence boards and posts to the new 2x4s before removing the old ones by cutting the nails with a sawmill.

I always build with screws because then it is simple to remove and replace fence boards. If you needed to maintain such a fence years from now it would be easy to disassemble it and rebuild it after replacing whatever wood needed to be replaced. You can’t do that with nails. Nails are one-time-only fasteners. Screws minimize waste by enabling non-destructive maintenance. Nails increase future waste by ensuring that maintenance requires extra time and materials and cost. Wasted money is still waste.

Another opportunity to minimize waste occurs when there are chunks of concrete left over, such as when a post base was cracked and some or all of it needed to be replaced. The chunks left over can either be taken to the dump or used somehow on the property. I try to suggest creative ways people can use this “urban crete” in their yards.

Of course it can also be disposed of. It costs $29 for 500 pounds at the Berkeley Transfer Station - just slightly more than it costs to buy regular concrete (not the kind I use). If I do it for a client it is probably an hour of labor plus the dump fees - so a bit over $100. You cannot load your municipal garbage bin with concrete - there is a weight limit for them that is quickly reached when you add concrete.

The problem with disposal is moving it. It is heavy. When I dump it at the Berkeley Transfer Station it gets pushed around all day and shipped away at night. Even if it gets recycled it took a lot of fuel to get it to a point where it could be recycled. By then the carbon footprint has increased beyond whatever could have been recovered through recycling.

Reuse on-site is the best possible outcome, but hopefully not via adding yet more concrete. The goal is to minimize not only the use of concrete, but also to minimize the transportation of heavy materials. Any concrete I buy or throw away was transported multiple times, producing carbon dioxide in the atmosphere for every mile.

Redwood is Carbon Negative

One of the poetic bright spots of building fences from redwood is that California, FSC-certified redwood itself is a carbon negative product. Practically all of the carbon in wood comes from the atmosphere. The plant takes in CO2 and splits it up into carbon and O2. It lets the O2 go and we like to breath that stuff. It uses the carbon to make more wood. It gets all kinds of nutrients via its plant system, but it doesn’t get much carbon that way compared to how much it gets directly from the atmosphere via photosynthesis.

Wood is at about 50% carbon by weight, so 100 pounds of wood is 50 pounds. CO2 is about 27% carbon by weight. The oxygen in it weighs almost 73% by comparison. So, 50 pounds of carbon represents 185 pounds of CO2. Right off the bat wood takes more weight of CO2 out of the air than it actually weighs in your hands. That’s kinda cool at a tangible, human scale.

But, it takes fuel or energy of some kind to develop and utilize trees to make and distribute lumber. While it grows without our energy, it needs fuel of some kind and machines to harvest it, transport it out of the forest to a lumber mill. Move it around inside the lumber mill and turn it into lumber. Move that lumber around and ultimately deliver it to locations where it can be purchased by people like me. It probably moves several times, possibly onto and off of a train, ship and/or trucks.

But, even when you consider all of that FSC redwood is still carbon negative. In other words, using it takes CO2 out of the atmosphere just as well as not driving a car or not buying concrete.

The other side of the equation is that redwood is a renewable resource and all aspects of its husbandry, transportation and milling comprise 52,000 jobs in California (13.2 million jobs worldwide). It accounts for about $3.3 billion of annual payroll in California (over $600 billion worldwide).

I only buy FSC-certified wood products. That is my guarantee that they were sustainably harvested and that the foregoing is true. Redwood isn’t cheap like the pine people use to build houses. It costs 3x as much as pine. There is a huge demand for redwood and it is higher priced now than I can ever remember. I doubt the price is going down any time soon because the supply doesn’t expand very quickly. But, by buying only certified wood I support the growers who are good stewards of the land.

The story doesn’t end there though. If the wood has not been painted then it can be composted. Composting the wood at the end of life adds a super-bonus to the carbon footprint instead of causing a problem longer off in the future.

If wood ends up in a landfill, it is going to be converted into methane over time. If that escapes into the atmosphere (which we should assume it will) then it will be 30x worse than the comparable amount of CO2. If the wood ends up in a landfill then it didn’t really have a negative carbon footprint once it finally decomposes. Of course that could be a hundred years or more in the future because materials in landfills tend to decompose very slowly.

But, if the wood is composted then it becomes soil that hosts a wide variety of creatures, plants and fungi. All of the carbon in those creatures comes from what they eat, which begins with the wood but quickly evolves into eating each other. The carbon for bugs doesn’t come from the atmosphere because they breathe oxygen. The plants get their carbon from the atmosphere, but fungi get it by eating things. And, both bugs and fungi eat the plants, which draws carbon from the atmosphere into the bugs and fungi as they grow.

If the compost is used to provide new ground soil or to amend problematic ground soil it will continue to support new organisms, capturing additional carbon from the atmosphere over time.

I see a lot of old fences. Many have unpainted fence boards more than 50 years old that are still serviceable. Pets can’t get through and they offer some privacy. If one does paint a fence it doesn’t help that much. The paint will crack because of natural expansion and contraction in the wood and water will carry the same bacteria and fungi into contact with the wood that would have been there, except that now there is a crack they can hide in while trying to consume the wood. Thats why you see blackened cracks in white painted fences. Ultimately the wood inside will rot about a little slower than if it wasn’t painted.

But, you’d have to keep painting it every few years. Paint isn’t cheap and it takes time and effort to paint a fence. Over the life of the fence you’d be paying for it many times in the cost of paint and effort to keep it painted. And the carbon footprint of paint isn’t great, because pigments come from minerals which must be mined and from petroleum products which are obviously carbon positive.

So, an unpainted FSC redwood fence, reusing existing concrete post bases has the the very lowest carbon footprint. If minimizing cost is also important wood can be reused if it is still serviceable (usually just the fence boards can be reused). But, even if aesthetics trump cost among priorities an all-new wooden fence can still be built reusing existing post bases. More wood actually equals an even lower carbon footprint.

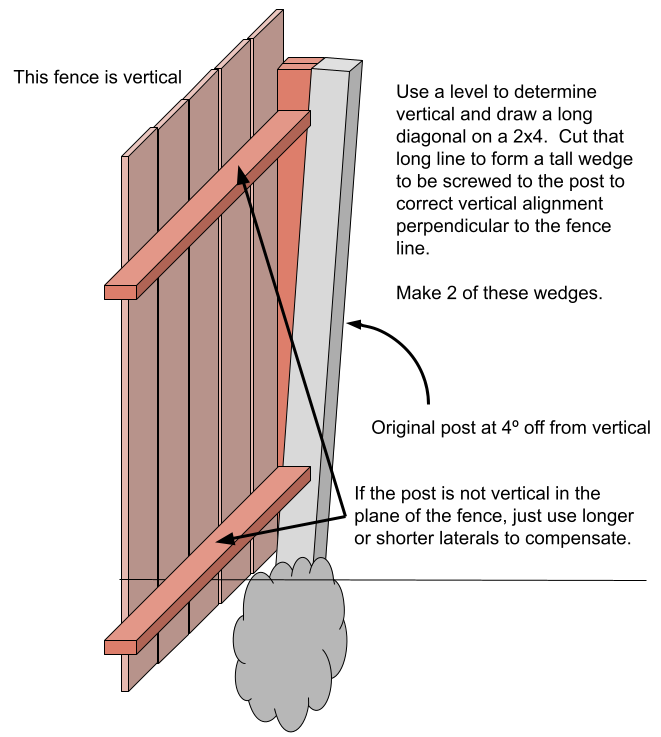

Why Not Pressure Treated Wood?

I don’t use pressure treated wood except for retaining walls. And, I don’t build retaining walls over 11.5” tall (a 2x12). Taller than that probably requires a retaining wall designed by an engineer.

Pressure treated wood is made from hem fir or other white wood that has no natural protection from insects, bacteria nor fungus. It is essentially candy to these creatures. Once they get a foothold it is only a matter of time until all the wood is consumed.

The wood is coated with a wood preservative that also stains the wood. The coating used to contain arsenic, but since the end of 2003 it has contained a copper compound instead, plus an insecticide called Azol. The wood is placed in a pressure vessel to drive the compound deeper into the wood. The surface of the wood has characteristic lines pressed into it to provide more surface area through which the compound can soak into the wood.

As long as nothing breaches the coating the white, untreated wood inside is safe. But, wood cracks over time. Sometimes people put in a nail and take it back out. Or a took gouges the surface exposing untreated fibers underneath. Possibilities like these and others mean that the wood is like a balloon, waiting to be popped. One any breach occurs in the surface the game is up and the wood will rot from within. I’ve grabbed onto pressure treated wood only to have it collapse into a handful of treated outer fibers.

I don’t use pressure treated wood for posts nor for laterals because it has a bunch of problems:

Do you really need more reasons?

Ok, sure:

The Bottom Line

The bottom line counts. The final cost of the project matters. It matters to my clients and it matters to me. I am always trying to minimize costs without sacrificing the result. Many people buy based on cost and they already have to get their heads around how I don’t make bids, only estimates. But, that too is about charging people the lowest possible cost that is also fair to everyone. Too often in life the alternatives we face are either green or inexpensive. It is really refreshing when a green choice is also the less expensive choice. It’s doubly nice when the products we use give people good, sustainable jobs.

Fences last a long time, but most houses have a lot of fencing. It’s ubiquitous. There are a lot of post bases out there… In any neighborhood some fence within a few hundred yards needs repairs or replacement. It’s a need almost every homeowner faces sooner or later. It’d be great for that to all be carbon negative.

Full disclosure: I drive a big, gasoline fueled cargo van from 2000 because I regularly haul a couple thousand pounds of materials or debris. This is the smallest vehicle that can serve the purpose to which I put it. A smaller vehicle would need to make more trips to transport the same load I can in one trip.

The rest of this blog post is about the fence project itself. These are my “first principles” of reducing the carbon footprint of fences

- Do nothing at all if the fence doesn’t need to be replaced or repaired

- Minimize the use of new concrete by reusing existing post bases

- Maximize the life of existing wood by reusing fence boards and laterals (2x4s)

- Minimize waste by buying the right size of lumber, composting unpainted wood and reusing urban crete (chunks of solid concrete).

- Minimize transportation of heavy materials

It is also usually the case that following these first principles also leads to a lower cost project, which is nice.

I’ve already written why concrete is so bad for the planet here. That’s why I try to minimize its use.

Replacing Fence Posts

I often replace posts by reusing the existing post base - I have a good blog post with pictures about how to do that. But, sometimes the post bases have issues, such as:

- The post base might be cracked, deteriorated, too thin or simply missing

- The post base may have rolled so the post it would hold wouldn’t be vertical

In the first case the post base simply cannot be reused. It has to be cracked out, at least partially. If it is cracked I remove the cracked parts and leave behind as much of the original post base as possible, unless it is less than half of a post base. If it is less than half I will usually remove it all.

I use fast-setting concrete. I never use “fence post concrete”. The kind I use is quite adhesive and will stick to the concrete already in the hole. It still needs to be 2” thick or thicker at its thinnest points, which are near the corners of the post. If the original post base isn’t at least 2” thick at the corners of the post it probably won’t survive the process of driving in a new post even if you are able to clear it.

But, in my experience a post base can usually be cleared and reused. I’d say more than 75% of the post bases I deal with are more or less easily reused.

Building a Vertical Fence on Leaning Posts

Recently I repaired and rebuilt two different fences where the post bases had rolled. I replaced the posts but they weren’t in any kind of line and they weren’t vertical. I certainly could have built a fence that wasn’t vertical nor straight but there is a better approach that yields a perfectly vertical fence regardless of the position of the posts. It requires a little more wood and woodworking.

Almost regardless of the fence design, the end result will have to include posts that are in line and vertical. But, only one side of the post needs that. The other sides of the post do not need to be vertical nor in a line.

I add wood to one side of the posts that aren’t plumb and in line. Post bases tend to roll so the angled post would point away from the fence. They can also roll along the fence line, but is much less of a problem because you can just use shorter or longer laterals to compensate for that. The hardest problem is the one that comes up most often: correcting for a post that leans away from the fence.

Typically I add a wedge of wood, but you can also add a wider piece of wood, such as a 2x8. But, redwood 2x8s are expensive and I can cut a 2x4 into two wedges that will work just as well as attaching a more expensive 2x8 to the side.

To check the alignment of the posts I attach a string to both end posts. Typically the posts all lean in the same direction but they might not. I have had fences with snaggletooth posts in all directions that could only be addressed by adding 2x12s to each post. It all starts by finding a straight line that none of the posts cross and building the rest of them out to that line.

To extend a post to the new fence line (defined by the string, which remains during this whole process) I add wedges and shims made from redwood 2x4s. I like using the rough 2x4s instead of the smooth S4S 2x4s because they are slightly thicker and wider.

I add the wedges first and then add shims as needed to reach the fence line.

| | To make the wedges I start by clamping a 2x4 to the leaning post and using a level to draw a vertical line on it. I don’t care whether the 2x4 is vertical in the plane of the fence (toward or away from adjacent posts), only whether it is vertical perpendicular to the fence line (where it leans away from the fence line). If the 2x4 doesn’t reach the fence line at the top because the post is leaning too far, you might need to add a second wedge. You make that one the same way, but it will be much shorter. Whatever wedge you make out of a 2x4, you’ll need two of that shape, side-by-side to act like a 4x4. I use 3” screws through from both sides of the pair to hold them together. To attach the wedges I use a variety of screw sizes. I want at least 1” of threads inside the 4x4 behind each section of wedge. I commonly use up to 3.5” screws which means I can screw a wedge as wide as 2.5”. But, the top of the wedge might be a full 3.5” wide and a longer screw won’t work as-is. |

I only ever use T25 star drive screws. I never use Philips head screws or square drive screws; however, I do swear at them and direct my ire toward them when I am forced to remove them.

Once the wedges are on then the rest of the gap from that point to the fence line needs to be occupied by solid wood. I prefer to use the rough 2x4s, but resting across the two wedges. That allows me to add 1.5” at a time. If it is going to need more than one 2x4 I will sometimes add a 4x4 instead. If I do, I drill 3/8” holes 1” deep and insert 3.5” screws in them to secure the 4x4 to each of the wedges behind it.

If I need 3/4” I will use a fence board to fill the gap, but only a really solid red one (construction heart).

If I need other thicknesses I will sometimes rip them from 2x4s on a tablesaw. That makes strips as wide as a 2x4 and the correct thickness for your needs. I attach those last, on top of any other shims and on top of all of the wedges. When you finally attach a fence board there be sure to use longer screws than usual so that the fasteners go through these thinner, custom shims.

It takes about half an hour to add wood to a post to make it have a vertical front. No new post base is needed. A new fence or a rebuilt fence made on the new combination post will be as vertical as the side you prepared with wedges and shims.

Minimizing Waste

There are lots of advantages to minimizing waste. First, there is less to throw away at the dump or in your trash. That is a good thing by itself because it saves you time and probably money if you have a nontrivial amount of waste.

Some waste can’t be avoided, such as rotted or broken wood. But other waste is tied to what you buy and how you use it. I have the luxury of using leftover wood on my next project and that is one way I reduce waste. Another way is in my choice of lengths. If I am building a fence with 6’ sections I buy 2x4x12s. If they are 7’ or 8’ sections I buy 2x4x8s. My goal is less than 10% waste in what I buy. When I do a good job there are only end-cuts left and it doesn’t take long to clean up.

Another aspect to minimizing waste is not assuming the existing fence is all waste. Often the fence boards can be reused with 20+ years of life in them. If you can push a finger into them they are too deteriorated to be used. The laterals may be rotted, but you can put new ones in place and attach all the fence boards and posts to the new 2x4s before removing the old ones by cutting the nails with a sawmill.

I always build with screws because then it is simple to remove and replace fence boards. If you needed to maintain such a fence years from now it would be easy to disassemble it and rebuild it after replacing whatever wood needed to be replaced. You can’t do that with nails. Nails are one-time-only fasteners. Screws minimize waste by enabling non-destructive maintenance. Nails increase future waste by ensuring that maintenance requires extra time and materials and cost. Wasted money is still waste.

Another opportunity to minimize waste occurs when there are chunks of concrete left over, such as when a post base was cracked and some or all of it needed to be replaced. The chunks left over can either be taken to the dump or used somehow on the property. I try to suggest creative ways people can use this “urban crete” in their yards.

- You can use urban leftover concrete chunks for a variety of purposes:

- You can add a border to an area to create a terrace with a line of concrete chunks

- You can stabilize an existing slope edge

- You can pile it in circles around trees and plants

- You can stack it in areas where dogs dig to discourage them from digging

- You can bury it

- You can break it into smaller pieces that suit your needs or disappear into soil more easily

Of course it can also be disposed of. It costs $29 for 500 pounds at the Berkeley Transfer Station - just slightly more than it costs to buy regular concrete (not the kind I use). If I do it for a client it is probably an hour of labor plus the dump fees - so a bit over $100. You cannot load your municipal garbage bin with concrete - there is a weight limit for them that is quickly reached when you add concrete.

The problem with disposal is moving it. It is heavy. When I dump it at the Berkeley Transfer Station it gets pushed around all day and shipped away at night. Even if it gets recycled it took a lot of fuel to get it to a point where it could be recycled. By then the carbon footprint has increased beyond whatever could have been recovered through recycling.

Reuse on-site is the best possible outcome, but hopefully not via adding yet more concrete. The goal is to minimize not only the use of concrete, but also to minimize the transportation of heavy materials. Any concrete I buy or throw away was transported multiple times, producing carbon dioxide in the atmosphere for every mile.

Redwood is Carbon Negative

One of the poetic bright spots of building fences from redwood is that California, FSC-certified redwood itself is a carbon negative product. Practically all of the carbon in wood comes from the atmosphere. The plant takes in CO2 and splits it up into carbon and O2. It lets the O2 go and we like to breath that stuff. It uses the carbon to make more wood. It gets all kinds of nutrients via its plant system, but it doesn’t get much carbon that way compared to how much it gets directly from the atmosphere via photosynthesis.

Wood is at about 50% carbon by weight, so 100 pounds of wood is 50 pounds. CO2 is about 27% carbon by weight. The oxygen in it weighs almost 73% by comparison. So, 50 pounds of carbon represents 185 pounds of CO2. Right off the bat wood takes more weight of CO2 out of the air than it actually weighs in your hands. That’s kinda cool at a tangible, human scale.

But, it takes fuel or energy of some kind to develop and utilize trees to make and distribute lumber. While it grows without our energy, it needs fuel of some kind and machines to harvest it, transport it out of the forest to a lumber mill. Move it around inside the lumber mill and turn it into lumber. Move that lumber around and ultimately deliver it to locations where it can be purchased by people like me. It probably moves several times, possibly onto and off of a train, ship and/or trucks.

But, even when you consider all of that FSC redwood is still carbon negative. In other words, using it takes CO2 out of the atmosphere just as well as not driving a car or not buying concrete.

The other side of the equation is that redwood is a renewable resource and all aspects of its husbandry, transportation and milling comprise 52,000 jobs in California (13.2 million jobs worldwide). It accounts for about $3.3 billion of annual payroll in California (over $600 billion worldwide).

I only buy FSC-certified wood products. That is my guarantee that they were sustainably harvested and that the foregoing is true. Redwood isn’t cheap like the pine people use to build houses. It costs 3x as much as pine. There is a huge demand for redwood and it is higher priced now than I can ever remember. I doubt the price is going down any time soon because the supply doesn’t expand very quickly. But, by buying only certified wood I support the growers who are good stewards of the land.

The story doesn’t end there though. If the wood has not been painted then it can be composted. Composting the wood at the end of life adds a super-bonus to the carbon footprint instead of causing a problem longer off in the future.

If wood ends up in a landfill, it is going to be converted into methane over time. If that escapes into the atmosphere (which we should assume it will) then it will be 30x worse than the comparable amount of CO2. If the wood ends up in a landfill then it didn’t really have a negative carbon footprint once it finally decomposes. Of course that could be a hundred years or more in the future because materials in landfills tend to decompose very slowly.

But, if the wood is composted then it becomes soil that hosts a wide variety of creatures, plants and fungi. All of the carbon in those creatures comes from what they eat, which begins with the wood but quickly evolves into eating each other. The carbon for bugs doesn’t come from the atmosphere because they breathe oxygen. The plants get their carbon from the atmosphere, but fungi get it by eating things. And, both bugs and fungi eat the plants, which draws carbon from the atmosphere into the bugs and fungi as they grow.

If the compost is used to provide new ground soil or to amend problematic ground soil it will continue to support new organisms, capturing additional carbon from the atmosphere over time.

I see a lot of old fences. Many have unpainted fence boards more than 50 years old that are still serviceable. Pets can’t get through and they offer some privacy. If one does paint a fence it doesn’t help that much. The paint will crack because of natural expansion and contraction in the wood and water will carry the same bacteria and fungi into contact with the wood that would have been there, except that now there is a crack they can hide in while trying to consume the wood. Thats why you see blackened cracks in white painted fences. Ultimately the wood inside will rot about a little slower than if it wasn’t painted.

But, you’d have to keep painting it every few years. Paint isn’t cheap and it takes time and effort to paint a fence. Over the life of the fence you’d be paying for it many times in the cost of paint and effort to keep it painted. And the carbon footprint of paint isn’t great, because pigments come from minerals which must be mined and from petroleum products which are obviously carbon positive.

So, an unpainted FSC redwood fence, reusing existing concrete post bases has the the very lowest carbon footprint. If minimizing cost is also important wood can be reused if it is still serviceable (usually just the fence boards can be reused). But, even if aesthetics trump cost among priorities an all-new wooden fence can still be built reusing existing post bases. More wood actually equals an even lower carbon footprint.

Why Not Pressure Treated Wood?

I don’t use pressure treated wood except for retaining walls. And, I don’t build retaining walls over 11.5” tall (a 2x12). Taller than that probably requires a retaining wall designed by an engineer.

Pressure treated wood is made from hem fir or other white wood that has no natural protection from insects, bacteria nor fungus. It is essentially candy to these creatures. Once they get a foothold it is only a matter of time until all the wood is consumed.

The wood is coated with a wood preservative that also stains the wood. The coating used to contain arsenic, but since the end of 2003 it has contained a copper compound instead, plus an insecticide called Azol. The wood is placed in a pressure vessel to drive the compound deeper into the wood. The surface of the wood has characteristic lines pressed into it to provide more surface area through which the compound can soak into the wood.

As long as nothing breaches the coating the white, untreated wood inside is safe. But, wood cracks over time. Sometimes people put in a nail and take it back out. Or a took gouges the surface exposing untreated fibers underneath. Possibilities like these and others mean that the wood is like a balloon, waiting to be popped. One any breach occurs in the surface the game is up and the wood will rot from within. I’ve grabbed onto pressure treated wood only to have it collapse into a handful of treated outer fibers.

I don’t use pressure treated wood for posts nor for laterals because it has a bunch of problems:

- It twists and bends terribly

- Every time you cut it the cut end must be treated with wood preservative otherwise it will begin to rot right away

- It stains other wood, clothing and skin with toxic chemicals

Do you really need more reasons?

Ok, sure:

- It cannot be taken to the dump in California because it is classified as toxic waste - none of your off-cuts can be put in your municipal garbage either.

- If you put it in the sun the top will shrink and the bottom won’t and it will warp - same if you use it as a top rail on a fence

- You cannot reliably correct warping once it happens

- Pressure treated 4x4s are often made from tree cores, left over from when the tree was shaved to make thin sheets for plywood. The core is the least stable part of the tree.

The Bottom Line

The bottom line counts. The final cost of the project matters. It matters to my clients and it matters to me. I am always trying to minimize costs without sacrificing the result. Many people buy based on cost and they already have to get their heads around how I don’t make bids, only estimates. But, that too is about charging people the lowest possible cost that is also fair to everyone. Too often in life the alternatives we face are either green or inexpensive. It is really refreshing when a green choice is also the less expensive choice. It’s doubly nice when the products we use give people good, sustainable jobs.

Fences last a long time, but most houses have a lot of fencing. It’s ubiquitous. There are a lot of post bases out there… In any neighborhood some fence within a few hundred yards needs repairs or replacement. It’s a need almost every homeowner faces sooner or later. It’d be great for that to all be carbon negative.

Wood shortages during the coronavirus pandemic

02/08/20 17:58

Wood is becoming scarce and that is not good for a builder of fences. Since California began allowing outdoor construction again I have found it very hard to find the kind of wood I need to make fences. I need three kinds of redwood:

I’ve had an easier time getting 4x4s and 2x4s than I have with the pickets, which are essentially unavailable at places like Home Depot. I am sometimes able to get them at Truitt & White. Ashby lumber had some for a while, but at 3x their normal price.

Lately I’ve been making more fences and gates with welded wire (2”x4” grid), hog wire and cattle fencing (both 4” square grid) instead of pickets. I can get 2x4s and 4x4s and the metal wire fence sections or rolls and build a fence that way, but it isn’t opaque. It is, however, completely adequate to contain a dog.

There are some alternatives to redwood pickets that are at least worth considering. First, there are cedar pickets. Cedar is what they used to make roof shingles out of, because it lasts a long time. Like redwood it is naturally resistant to insects and rot. The best specimen of redwood is better at that than the best specimen of cedar, hands down. But, fence boards aren’t made from the best specimens of redwood. They are often made from “Construction common” redwood, which includes both heart wood and sap wood (when it doesn’t contain *mostly* sapwood.) Sapwood isn’t very resistant to rot or insects.

In the photo above the pink part is the heart wood. It is cracked on top, but even though water got into those cracks the rot didn’t get very far into the pink part. The white part is the sap wood. The holes were made by termites. They didn’t like the pink part because it probably tastes bad to them. The tannin in the pink part has anti-nutritive properties, so if the insects eat the pink part they starve. They probably know to avoid it by taste.

Cedar has sapwood too, but it is a thin layer. And, it usually gets milled away so it won’t be in your fence boards. There are no “construction common” cedar fence boards: they are all heart wood.

The best western red cedar boards are better than the worst redwood boards, especially where there is a lot of sap wood in the redwood board. I’ve seen fence boards that are completely sap wood and no pink heartwood at all. Of course I won’t buy those, but someone does. Those boards are worse than the cedar fence boards.

So, cedar is a decent alternative for fence boards, while it lasts. But it also needs to be milled and supplies of it are bound to run short as well.

So, if I cannot get wood some projects simply won’t be actionable until I can get it. I may have to resort to buying in large lots from a manufacturer, or I may have to temporarily work only on fence repair and not replacement or new fences. In other words: replacing fence posts.

My current queue of projects is about 6 months long. There is a mix of new fences and fence repairs. If I cannot get fence boards I’ll focus on repairs until I can get them. There isn’t much else I can do. It amounts to rearranging my schedule and disappointing clients with additional delays, possibly after they have waited many months for execution of their project.

There are more expensive alternatives to normal redwood fence boards. More and more clients like to use smooth construction heart wood mounted horizontally. Others like the next better grade called “Heart B” which is heartwood with very few knots (but not none). Eventually supplies of those will run out of the mills do not resume making more, but it is an expensive alternative to regular, rough fence boards, especially when compared with cedar pickets which are already a lot less expensive than the least expensive version of redwood pickets.

There are other kinds of fences that I don’t actually make for people, including steel fences, cyclone fences, stone, concrete or masonry walls and landscape fences (such as a tight row of bamboo). These all might be practical alternatives to a wooden fence depending on people’s needs.

They say that good fences make good neighbors, but for the right neighbors a row of pebbles would be enough.

- 4x4 posts, either 8’ and 10’ long

- 2x4 laterals, 8’, 10’ and 12’ long

- pickets (aka fence boards), usually 7.5” wide and 6’ long and 3/4” thick

I’ve had an easier time getting 4x4s and 2x4s than I have with the pickets, which are essentially unavailable at places like Home Depot. I am sometimes able to get them at Truitt & White. Ashby lumber had some for a while, but at 3x their normal price.

Lately I’ve been making more fences and gates with welded wire (2”x4” grid), hog wire and cattle fencing (both 4” square grid) instead of pickets. I can get 2x4s and 4x4s and the metal wire fence sections or rolls and build a fence that way, but it isn’t opaque. It is, however, completely adequate to contain a dog.

There are some alternatives to redwood pickets that are at least worth considering. First, there are cedar pickets. Cedar is what they used to make roof shingles out of, because it lasts a long time. Like redwood it is naturally resistant to insects and rot. The best specimen of redwood is better at that than the best specimen of cedar, hands down. But, fence boards aren’t made from the best specimens of redwood. They are often made from “Construction common” redwood, which includes both heart wood and sap wood (when it doesn’t contain *mostly* sapwood.) Sapwood isn’t very resistant to rot or insects.

In the photo above the pink part is the heart wood. It is cracked on top, but even though water got into those cracks the rot didn’t get very far into the pink part. The white part is the sap wood. The holes were made by termites. They didn’t like the pink part because it probably tastes bad to them. The tannin in the pink part has anti-nutritive properties, so if the insects eat the pink part they starve. They probably know to avoid it by taste.

Cedar has sapwood too, but it is a thin layer. And, it usually gets milled away so it won’t be in your fence boards. There are no “construction common” cedar fence boards: they are all heart wood.

The best western red cedar boards are better than the worst redwood boards, especially where there is a lot of sap wood in the redwood board. I’ve seen fence boards that are completely sap wood and no pink heartwood at all. Of course I won’t buy those, but someone does. Those boards are worse than the cedar fence boards.

So, cedar is a decent alternative for fence boards, while it lasts. But it also needs to be milled and supplies of it are bound to run short as well.

So, if I cannot get wood some projects simply won’t be actionable until I can get it. I may have to resort to buying in large lots from a manufacturer, or I may have to temporarily work only on fence repair and not replacement or new fences. In other words: replacing fence posts.

My current queue of projects is about 6 months long. There is a mix of new fences and fence repairs. If I cannot get fence boards I’ll focus on repairs until I can get them. There isn’t much else I can do. It amounts to rearranging my schedule and disappointing clients with additional delays, possibly after they have waited many months for execution of their project.

There are more expensive alternatives to normal redwood fence boards. More and more clients like to use smooth construction heart wood mounted horizontally. Others like the next better grade called “Heart B” which is heartwood with very few knots (but not none). Eventually supplies of those will run out of the mills do not resume making more, but it is an expensive alternative to regular, rough fence boards, especially when compared with cedar pickets which are already a lot less expensive than the least expensive version of redwood pickets.

There are other kinds of fences that I don’t actually make for people, including steel fences, cyclone fences, stone, concrete or masonry walls and landscape fences (such as a tight row of bamboo). These all might be practical alternatives to a wooden fence depending on people’s needs.

They say that good fences make good neighbors, but for the right neighbors a row of pebbles would be enough.

Fence Repair

07/03/20 16:20

Should I replace or repair my fence?

Most people I talk with who have problems with their redwood fences assume that their fence will need to be replaced. In fact that tends to be true less than half the time in my experience. Often there are parts of a fence that have many more years of useful life in them and repair is a viable and much less expensive option.

About Redwood

This is all about redwood and redwood fences. Redwood has both a pink portion of wood and portions that are variously faded toward white or are entirely white. The color comes in part from the tannin in the wood, or at least the pinker the wood, the more tannin is present. The tannin inhibits bacterial and fungal growth, and repels insects. It “tastes bad” but and has anti-nutritional properties by interfering with the digestion of whatever consumes it.

Here is a photo of a cross-section of construction common redwood 2x6 that was the top lateral on a deck’s railing. It has been weathered on the top. The cracks on top are caused because the wood shrunk more on the top than anywhere else. It shrunk there because it was always in the sun and it dried out more. Also the direction of the grain in this piece would mean it would cup downward. The pith of the rings expand and contracts more than the edges of rings. Fence pickets also cup in the same direction: boards cup away from the center of the tree.

You can see the pink part and the white part of this piece. Redwood doesn’t always change as discretely from pink to white as in this piece. The pink part has a lot more tannin in it than the white part. You can see that termites have eaten the white part and left the pink part almost completely untouched. It looks like they ate right up to the pink part and then carefully avoided it; or, the ones who ate it died.

Had this piece been consistently coated it would have kept the moisture in the wood and it might not have cracked or not as badly, but it would still cup as it dried, so the paint on top would crack too. The cracks let in water and with it microbes and fungus which also try to consume the wood. But you can see they haven’t been very successful. The dark stain around each crack marks the extent of their infiltration into the wood, at best.

This piece was construction common, which includes both pink and white portions of the wood. You can also buy construction heart wood which is not supposed to have any white portion. I used construction heart for the posts and laterals, but I use construction common pickets. I exclude any pickets with more than a small amount of white in them. A little bit is OK especially if it doesn’t go all the way through the picket. Even if it rotted, so long as the fence remains a fence and serves its purpose of providing privacy I think it is OK to use.

You might not know it, but even taking all manufacturing and transportation into account, building with California FSC certified redwood has a net negative effect on atmospheric CO2. All of the carbon in a piece of wood comes from the atmosphere. The roots provide nutrients to enable the process, but practically all the carbon in wood come from the air. The carbon footprint of a fence project can be reduced by using a polyurethane foam for post bases or by reusing existing concrete post bases.

Fence Repair

First, here are the parts of a redwood fence:

1. The posts (usually 4x4s)

2. The laterals that go between and possibly on top of the posts (usually 2x4s)

3. The pickets (aka “fence boards”)

Good Neighbor fences also have horizontal 1x1 strips attached to the laterals covering the ends of the fence boards and physically retaining them. Other designs also have additional horizontal wood pieces, but these aren’t actually structural and their failure would be an aesthetic problem and not one that would lead to the failure of a fence, assuming it was correctly built.

Posts

Posts rot at the ground level if they come into contact with dirt. This is the most common cause of fences failing. They lean or wobble or fall over when the posts fail. Often plants growing on a fence keep the fence up long after it would have fallen without them. Fortunately it is possible to fix rotted posts without replacing the rest of the fence, nor in general damaging the plants on the fence.Here is a detailed article on how to replace fence posts without harming the rest of the fence.

You can make your fence last a lot longer by ensuring that dirt doesn’t come into contact with the bottom of the post, where it reaches the ground. You can dig away the dirt to expose the post, but it may already be rotted. If it is you can spray it with a wood preservative to help arrest the problem, if it isn’t too late.

I will sometimes dig away the dirt and then pour new concrete to form a berm around the post, raising the concrete up above the soil level. Of course over time the soil level may rise because new dirt forms from decomposing leaves, so you’d have to keep the top of the berm visible over time. When I do use concrete I form a berm around the post base when I create it. if I am using polyurethane foam it naturally expands high enough above the soil level that I can cut a berm into post base. The goal is for water to roll away from the post and not sit next to the post. I make an inverted bowl shape.

Laterals

The laterals sometimes rot, especially if plants grow over the fence and drop leaves on them. The leaves fall on the laterals and stay there. They decompose there. They become dirt there. Redwood rots when in contact with dirt. It takes a long time for leaves to become dirt, but in the scale of the life of a fence, it happens pretty quickly - a few years is enough to start the rot process. If the laterals are in the shade that means the dirt won’t dry out and the rot happens faster and sooner. If it is in bright sun that will help slow the rotting process by drying out the dirt. But, it will still rot when it is wet.If I have to replace laterals I will first cut the old lateral out of the fence. I do that by cutting the fasteners with a sawzall and a metal-cutting blade. If there are screws I try to remove them with an impact driver if possible, because screws are made of much harder steel than nails and it damages/uses up the blades much sooner. I cut or remove the fasteners that hold the pickets on first, and then I cut the ones that hold the lateral to the posts second. Since most fences I repair are made with nails, I cut them all. It is impractical to try to remove the nails, and the old pickets may split or break if you try.

Pickets

The pickets fail least often. Aside from physical breaks such as when one gets kicked or broken when someone climbs over, thy only real failure modes are decay, termites and deterioration under daily UV light. A picket in the sun during the day from both sides will not rot, but it will slowly wither away under the UV light. First the outside turns gray but the inside is still pink or red. As time goes on the inside gets less and less red and more and more brown. Tannin is water soluble. Over time as the wood’s water content changes back and forth the tannin leaches out . As it dries it may split, letting in moisture and microbes (fungi and bacteria) and possibly even insects. Over time the tannin goes away and then the wood is vulnerable to rot and termites.

As the pickets age they will break more easily and they will bend or curl more and more. Knots are likely to have fallen out and in general, the pickets stop doing a good job of providing privacy.

Fences I replace are sometimes made of redwood pickets that have lasted 50+ years. But modern pickets probably won’t last that long because they are made from faster growing redwood trees. The growth rings are further apart and the wood is less durable as a result.

If a fence still has good pickets I try to replace the posts and laterals as necessary. But, I don’t replace the pickets unless they are so old that they will not last much longer anyway.

Pickets in good neighbor fences rot at the bottom because water and then dirt collects in the gaps between the 1x1 strips and the pickets. “Least Cost” style fences allow the water to fall off the bottom of the pickets. The pickets should never touch the ground though, or the bottoms will rot.

A Maintainable Fence

Nails suck.

Fences built with nails are difficult to maintain, difficult to repair, difficult to salvage and difficult to extend.

In the 1950s pneumatic nailers became popular and suddenly it was practical to drive a lot of nails quickly and easily. Now it is 70 years later and you can bet any fence still standing that was built with nails was most likely built with a pneumatic nailer. If you don’t see the wood bruised by a hammer around practically every nail then they weren’t hammered in.

People use pneumatic nailers because they are fast and efficient and reliable.

But nails suck. And fences built with nails are more difficult to maintain. When I cut fasteners sometimes pickets break anyway. Had they been screwed together that would not have been a problem.

I suppose there was a time when screws were expensive. The screws I use cost $30 for 5 lbs, which works out to be about a nickel or more each. Nails are still a lot cheaper than screws. But, it is a false economy to save money by using nails if it means the fence cannot be maintained.

What does it mean to maintain a fence? It means replacing boards, laterals or posts that have been broken, rotted prematurely, been discolored or have other defects. If the fence has been screwed together it can be maintained simply by removing the screws and then replacing the wood that has failed. If the fence has been nailed together that process is much harder at best.

Some fences can be built completely using screws - no nails at all. In particular, what I call a “least cost fence”, which is just posts, laterals and pickets on one side of the fence is one of the most maintainable fences that can be made. Also, it is less expensive to create, so some of the money saved can be used for repair in the future.

Some fences cannot be built completely with screws. In particular, the style of good neighbor fence depicted above is partially made with finish nails. The pickets are toe-nailed in at the bottom and top using 2” finish nails. The pickets are retained by 1x1 strips along the top and bottom of both sides. Those strips are often finished nailed in but they can be removed and replaced easily even if they were nailed in. Those strips can also be screwed in if they are pre-drilled and countersunk first. They some times do not survive being removed if they were nailed, so they end up needing new 1x1s for the repair, but 1x1s are inexpensive. Once the 1x1 has been removed individual pickets can be removed and replaced. When all the broken pickets in a section have been replaced a (possibly new) 1x1 is re-attached to finish the repair.

Screws

I use ceramic-coated T25 (star-drive) screws. They have a lifetime guarantee. I have used many thousands of these screws. I use hundreds in some fences alone and I make a lot of fences. That is a big lot of screws. Some are sunk once, others are temporary and are sunk and removed several times during the project.

None. Of. Them. Have. Ever. Had. A. Stripped. Head.

If you use Philips head screws, the ones that look like a plus sign, I must humbly ask you to stop doing that unless you hate the people who will have to maintain whatever it is that you are building. Philips head screws strip. The head of the screw gets chewed up and then you can’t get them out. It doesn’t always happen, but it happens a lot. The older the screw the more likely it has corroded and the more likely it will strip. You cannot sink and remove a Phillips head multiple times without it stripping.

There are important differences between the two head designs. A Philips head has interior sides that angle down from the top of the screw toward a point a bit below the top. It means the four corners against which your screw driver pushes are really triangles, not rectangles. You have to push in hard on a Philips head screw while you are trying to get it out otherwise your effort will instead push the screwdriver out of the head, stripping it somewhat in the process. Repeat a few times and that screw will not come out with a driver head ever again.

By comparison a star drive is vastly different. First, the star actually goes straight into the head of the screw. It does not have angled interior sides. So, each facet of the star, against which a facet of the driver bit pushes, is a rectangle, not a triangle. While you do need to maintain some pressure on the bit as it tightens or loosens the screw, you don’t need as much force as you would with a Phillips head screw because there is not much force to push the bit out of the star head.

And, if you’re thinking of using a flat head, please consult this article. And then use star head screws instead.

One or Two Fasteners?

Probably every fence you’ve ever seen had pickets that were attached with two nails. Or, if it was built to be maintainable, two screws. Probably every one of these fences had pickets that are splitting slightly (or a lot) at the top and bottom.

Also, on a related topic, how many fences have you seen where the pickets fell off because the nails or screws failed completely?

Two fasteners is problematic because wood expands and contracts with the relative humidity. Two fasteners trap the wood between them. If the wood is going to expand it will have to push the fasteners apart. If the fasteners won’t move, the wood will be crushed against the fasteners forming a bigger hole next to each fastener. If the wood is going to contract it will pull against the fasteners. If the fasteners won’t move the wood will be crushed against the inside edge or else the wood will split, or both.

Since the relative humidity changes with the weather and season the wood expands and contracts many times over its lifetime by more or less small amounts. Eventually the wood is both cracked and the holes around the fasteners have been enlarged, leading to loose fence boards that don’t come off but they might rattle or move.

I use one fastener per picket because I use screws that don’t fail, and because then the wood is free to expand and contract without apply any force to the screw or itself. It won’t crack either, so water can’t get in to begin the rotting process.

Furniture made from solid wood must be made to account for wood movement. Cabinet doors with floating panels are made that way so that the panels don’t tear the frame apart when they expand and contract. Wood changes size with relative humidity. You can either take that into account as a woodworker or you can make things that slowly tear themselves apart.

The only challenge with using a single fastener is that you must choose an orientation for each fence board such that when it cups, it cups toward the 2x4 lateral to which it is attached.

The image below shows a stack of pickets. You are looking at the end grain. Under the stack is a 2x4. They are oriented how they should be oriented if each one was separately attached to that 2x4. If you turn them upside down in this photo and attach them, they would cup away from the 2x4 over time.

Sometimes it is too close to call, such as if the board is quarter sawn. In a quarter sawn piece the end grain would show vertical lines. It wouldn’t matter which way you attach a quarter sawn board, it probably will not cup much if at all.

If you are making a good neighbor fence it doesn’t matter as much because the wood is retained by the 1x1 strips, which resist the cupping effect somewhat. It may still cup a little, so you might want to orient them in a useful pattern, such as all the same way, or alternating so each adjacent picket cups in opposite directions.

Conclusion

Fences are temporary structures. If you don’t believe me you should see how fast I can take one down with a sawzall. They seem like walls, but they’re just woodworking projects. A maintainable fence is not really much more expensive to create than one that is a lot harder to maintain. If you have the tools and techniques then perhaps all fences are maintainable, but for the average DIY homeowner it makes more sense for fences to be built with screws where possible, and for those screws to be T25 star drive screws and not Phillips head screws. A least cost fence will last longer if each picket has only one screw at the top and one at the bottom (instead of two each at the top and bottom).And whatever you do keep dirt from contacting any part of your fence, especially at the post bases.